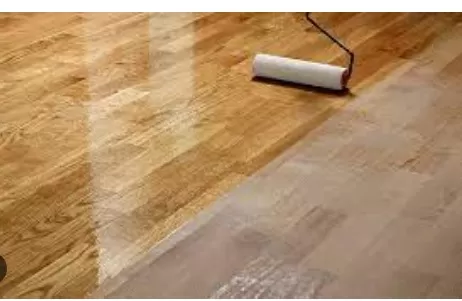

Choosing the Right Finish for Hardwood Floors: A Guide . When it comes to protecting your wood floors, whether they are newly installed or decades old and being refinished, selecting the right top coat is essential. Understanding the differences between various popular finishes will help you make an informed decision that suits your specific project.

With a wide range of options available, such as polyurethane, water-based finishes, oils, and more, it’s important to explore their characteristics and benefits. By familiarizing yourself with these eight popular finishes, you can choose the one that best meets your needs, ensuring the longevity and beauty of your wood floors.

Advantages and Recommendations for Water-Based Polyurethane for Hardwood Floors

Water-Based Polyurethane: A Clear and Fast-Drying Finish for Hardwood Floors.

Water-based polyurethane is an excellent choice for homeowners looking for a clear and quick-drying finish for their hardwood floors.

It offers several advantages, making it a popular option in the market.

Easy Application and Cleanup.

One of the significant benefits of water-based polyurethane is its ease of application.

Whether you hire professionals or prefer a DIY approach, this finish is user-friendly and can be applied with minimal effort. Additionally, cleanup is a breeze since water-based polyurethane can be easily cleaned up with water and soap.

Low Odor and Low VOCs.

Unlike other options, water-based polyurethane releases fewer volatile organic compounds (VOCs).

This is beneficial for both your health and the environment. During application, the low odor of this finish ensures a more comfortable and pleasant experience.

Smooth and Shiny Finish.

Water-based polyurethane provides a remarkably smooth and shiny finish, enhancing the natural beauty of hardwood floors.

Although it may appear slightly milky in the can, it dries to a crystal-clear finish that resists yellowing over time.

Scratch Magnification Consideration.

It’s important to note that high-gloss water-based polyurethane can magnify scratches and scrapes on the floor.

While this finish offers exceptional durability, homeowners should be cautious when opting for a high-gloss sheen, as imperfections may become more apparent.

Top Recommendations.

In our Buyer’s Guide for water-based polyurethane finishes, two products stood out as top performers: General Finishes’ High-Performance Water Based Top Coat and Bona’s Mega Wood Floor Finish.

These brands offer excellent quality and are widely recognized for their durability and finish.

Care and Maintenance.

Water-based polyurethane is relatively easy to maintain.

Regular sweeping and damp mopping will keep your hardwood floors looking pristine. However, it’s crucial to avoid waxing polyurethaned floors as it can dull the finish.

Environmental Friendliness.

If you prioritize environmentally friendly options, water-based polyurethane is an excellent choice.

With its low VOC emissions and eco-friendly formulation, this finish minimizes its impact on the environment while still delivering exceptional performance.

Quick Drying Time.

With water-based polyurethane, you won’t have to wait long for your floors to dry.

Typically, it only takes two to four hours between coats, making the application process more efficient. After the final coat, you can walk on your new floors within a few hours.

However, it’s recommended to wait at least 48 hours before moving heavy furniture back into place.

In conclusion, water-based polyurethane is a top choice for hardwood floor finishes.

Its clear and quick-drying properties, low odor and VOC emissions, and environmental friendliness make it an attractive option for homeowners. By following proper care and maintenance guidelines, you can enjoy the smooth and shiny finish of water-based polyurethane for years to come.

Oil-Based Polyurethane: Durable Finish for High-Traffic Areas

Oil-Based Polyurethane: A Long-Lasting Finish for High-Traffic Areas.

Oil-based polyurethane is a preferred choice for both commercial properties and high-traffic areas in residential homes.

Known for its durability and strength, this finish offers several advantages, although it also presents some considerations.

Notable Durability and Moisture Resistance.

The robust composition of oil-based polyurethane, comprising linseed oil, synthetic resins, and plasticizers, provides exceptional durability.

It is particularly suitable for high-traffic areas, as it withstands the wear and tear of daily use. Furthermore, this finish offers good moisture resistance, helping to protect the underlying wood from damage.

Easy Maintenance and Care.

Maintaining oil-based polyurethane floors is relatively straightforward.

Regular sweeping or vacuuming, along with occasional cleaning using a damp sponge, is usually sufficient to keep the floors looking clean and attractive.

Rich Amber Color and Finish Options.

Oil-based polyurethane exhibits a slight amber or yellowish tint, which can deepen over time.

This characteristic adds a warm and rich color to the floors, which some homeowners find desirable. Additionally, you can find this finish in high-gloss, semi-gloss, and satin sheens, allowing you to choose the level of shine that best suits your preferences.

Considerations for Oil-Based Polyurethane.

Slow Drying Time.

Compared to water-based polyurethane, oil-based polyurethane has a significantly longer drying time.

Each coat typically takes around eight to 10 hours to dry, and it is generally recommended to apply two to three coats. Therefore, you will need to allocate more time for the project to ensure proper drying and curing.

VOC Emissions and Odor.

Oil-based polyurethane releases a high level of volatile organic compounds (VOCs) during application, making it important to take appropriate precautions.

If you choose to apply this finish yourself, wearing a respirator is essential to protect your respiratory health. Additionally, the strong odor associated with oil-based polyurethane may require adequate ventilation during the application process.

Yellowing Over Time.

Over time, oil-based polyurethane tends to develop a deeper amber color and can yellow further.

While this may be desirable for some homeowners seeking a warm appearance, it is important to consider the long-term color changes that may occur.

Top Recommendations.

If you are considering oil-based polyurethane for your floors, several quality options are available.

Dura Seal Polyurethane for Wood Floors, Rust-Oleum Varathane Oil-Based Floor Finish, and Minwax Super Fast Drying Polyurethane for Floors are all reliable choices that offer durability and a range of sheen options.

Furniture Placement and Curing Time.

After the final coat, it is crucial to allow sufficient curing time before resuming regular use.

It is recommended to wait at least 48 hours before walking on the floors with shoes and four days before moving furniture back into the rooms.

In summary, oil-based polyurethane is a durable finish ideal for high-traffic areas.

Its strength, moisture resistance, and attractive amber color make it a popular choice. However, the longer drying time, VOC emissions, and odor require careful consideration.

By following proper application and curing guidelines, you can enjoy long-lasting and beautiful floors in your high-traffic spaces.

Moisture-Cure Urethane: The Ultimate Floor Finish for Tough Environments

Moisture-Cure Urethane: The Go-To Finish for High-Demand Situations.

Moisture-cure urethane is an exceptionally resilient and durable floor finish that was originally developed for bowling alleys.

Designed to withstand heavy use and harsh conditions, it offers unparalleled toughness in demanding environments. However, this finish comes with specific considerations that limit its suitability for DIY projects.

Exceptional Durability and Resistance.

The standout feature of moisture-cure urethane is its remarkable durability.

It provides superior resistance to moisture, scratches, stains, and general wear and tear. Originally formulated for commercial spaces like bowling alleys, dance halls, and restaurants, it offers long-lasting protection and a high-gloss appearance that can endure heavy foot traffic.

Challenges in Application.

Moisture-cure urethane presents challenges when it comes to application, making it less suitable for do-it-yourselfers.

Achieving an even application requires a skilled hand and experience. The finish dries to a high shine but requires a quick and precise application process due to its fast-drying nature.

High VOC Levels and Air Quality Concerns.

One significant downside of moisture-cure urethane is its high volatile organic compound (VOC) content.

The release of VOCs during application can result in strong odors and potentially impact air quality. It is crucial to note that these VOCs can linger in the air for weeks, necessitating the relocation of all household members during and after the application process, typically for up to two weeks.

Humidity Considerations.

Moisture-cure urethane is sensitive to humidity levels during application.

It draws moisture from the air to cure, meaning that the humidity on the day of application can significantly impact the drying process. If the air is too dry, the finish may not cure or dry evenly.

Conversely, in excessively humid conditions, it can start to dry prematurely, resulting in an uneven finish. Achieving an evenly spread and well-cured finish requires experience and careful monitoring of humidity levels.

Professional Application and Commercial Use.

Due to the complexities involved in its application and the challenges associated with VOC emissions, moisture-cure urethane is primarily used in commercial settings.

Professional contractors typically handle the application, utilizing reputable brands such as Dunham’s or Lenmar.

In summary, moisture-cure urethane is an exceptionally durable floor finish suitable for high-demand environments.

Its resistance to wear, moisture, and stains, along with its high-gloss appearance, make it a preferred choice for commercial spaces. However, the challenges in application, high VOC levels, and sensitivity to humidity limit its usage primarily to professional settings where its benefits outweigh the downsides.

Wax: A Classic and Low-Sheen Finish for Hardwood Floors

Wax: A Timeless and Natural Finish for Hardwood Floors.

Wax, an age-old hardwood floor finish, offers a low-sheen and natural appearance that is still favored in historic homes and by DIY enthusiasts.

While it provides several advantages, such as easy application and touch-ups, low odor and VOC emissions, and the ability to combine with stain, there are also considerations to keep in mind.

Versatility and Application.

Wax is available in both liquid and paste forms, and it can be applied to achieve a low-sheen finish.

Liquid wax is typically applied with a wool applicator, while paste wax is applied using a rag. Multiple coats of wax need to be manually buffed in by hand to achieve the desired result.

For those seeking a customized look, wood stain can even be mixed with the wax to add color during the finishing process.

Limited Durability.

One aspect to be aware of when using wax as a hardwood floor finish is that it does not provide a highly durable surface.

Exposure to water can result in white marks, making wax less suitable for bathrooms or kitchens. Additionally, waxed floors are prone to scuffing and scratching, although these can generally be easily buffed away and concealed with an additional coat of wax.

Yellowing or Darkening over Time.

Over the course of time, wax may develop a yellow or darkened appearance.

Therefore, it is best suited for use on wood with an existing warm hue. If you decide to transition from a wax finish to polyurethane, it is important to note that the wax must be completely stripped from the floor prior to applying the new finish.

Top Recommendations.

For those considering wax as a hardwood floor finish, Holloway House Pure Floor Wax and Lundmark All Wax are both reliable choices known for their quality and performance.

In summary, wax offers a classic and low-sheen finish for hardwood floors.

It is particularly popular in historic homes and among DIY enthusiasts seeking a natural appearance. While wax provides easy application and touch-up capabilities, low odor and VOC emissions, and the potential for color customization, it lacks the durability of other finishes.

Additionally, the potential for yellowing or darkening over time and the necessity of stripping the wax for a transition to a different finish should be taken into account.

Shellac: A Natural and Quick-Drying Finish for Wood Floors

Shellac: A Natural and Quick-Drying Finish for Wood Floors.

Shellac, derived from the secretions of the lac bug mixed with denatured alcohol, has been a popular choice for wood sealing and finishing for centuries.

It offers several advantages, such as being a natural and sustainable product, low VOC emissions, quick drying time, and ease of repair. However, there are considerations to keep in mind when using shellac as a hardwood floor finish.

Natural and Sustainable Option.

Shellac is a natural product made from renewable sources, providing an environmentally friendly choice for those seeking sustainable finishes.

It is derived from the secretions of the lac bug, combined with denatured alcohol. This natural composition makes shellac a desirable option for those who prioritize using organic materials in their homes.

Quick Drying and Easy Repairs.

One notable benefit of shellac is its quick drying time.

This allows for faster completion of the finishing process and minimizes the waiting period before the floors can be used. Additionally, shellac is easy to repair or touch up.

Simply buffing in a new coat of shellac can address any minor imperfections or wear.

Challenges in Application and Durability.

Shellac can be challenging to apply evenly, and lap lines may be visible if not applied with care.

While it naturally dries with an orange tint and high-gloss finish, it can be bleached or tinted to achieve desired aesthetics. However, it is important to note that shellac is far less durable than many other finish options available.

It is prone to staining, water spotting, and damage from alcohol and ammonia. Therefore, it may not be suitable for high-traffic areas or spaces where exposure to moisture is common.

Compatibility and Limitations.

While it is possible to buff wax over shellac, applying a polyurethane finish on top of shellac is not recommended.

If you decide to change the finish of your floors, complete removal of the shellac is necessary before applying a different type of finish.

Top Recommendation.

Zinsser’s Bulls Eye Clear Shellac is a quality shellac product that is well-regarded for use on wood floors.

In summary, shellac offers a natural and quick-drying option for wood floor finishes.

It is a sustainable choice with low VOC emissions and easy repair capabilities. However, its challenges in application, limited durability, susceptibility to staining and water spotting, as well as compatibility limitations with other finishes, should be taken into consideration when selecting shellac as a hardwood floor finish.

*The information is for reference only.